Uncategorized

-

NEW – ErectaStep’s non-penetrating rooftop stair solution

Introducing the Counterweight-Based Stair & Crossover Solutions Accessing rooftop equipment such as HVAC units, ductwork, or piping requires safe, compliant, and non-disruptive infrastructure. ErectaStep’s counterweight-based rooftop stair and crossover system provides a secure, non-penetrating access solution that protects roof integrity while ensuring worker safety. Non-Penetrating Rooftop Stair & Crossover System ErectaStep’s Non-Penetrating Counterweight-Based System CommercialRooftops…

-

SafeRack Celebrates a Stellar 2023!

Mount Pleasant, SC – Amidst the backdrop of the USS Yorktown, SafeRack’s sales team recently celebrated a year marked by unwavering commitment to safety and customer excellence. This gathering in Mount Pleasant, South Carolina, celebrated achievements and reaffirmed our core mission: to provide safe access solutions and unparalleled service in the field by enhancing Collaboration and…

-

Press Release – Upside Innovations Acquisition Expands Product Range

Falfurrias Capital Partners’ SixAxis manufacturing to expand safety and access product solutions with the acquisition of Upside Innovations Deal combines complementary firms in modular, mass-customized manufacturing of ramps, stairs, platforms and handrails CHARLOTTE, NORTH CAROLINA (June 2, 2021) – Charlotte-based private equity firm Falfurrias Capital Partners today announced it has facilitated the add-on acquisition…

-

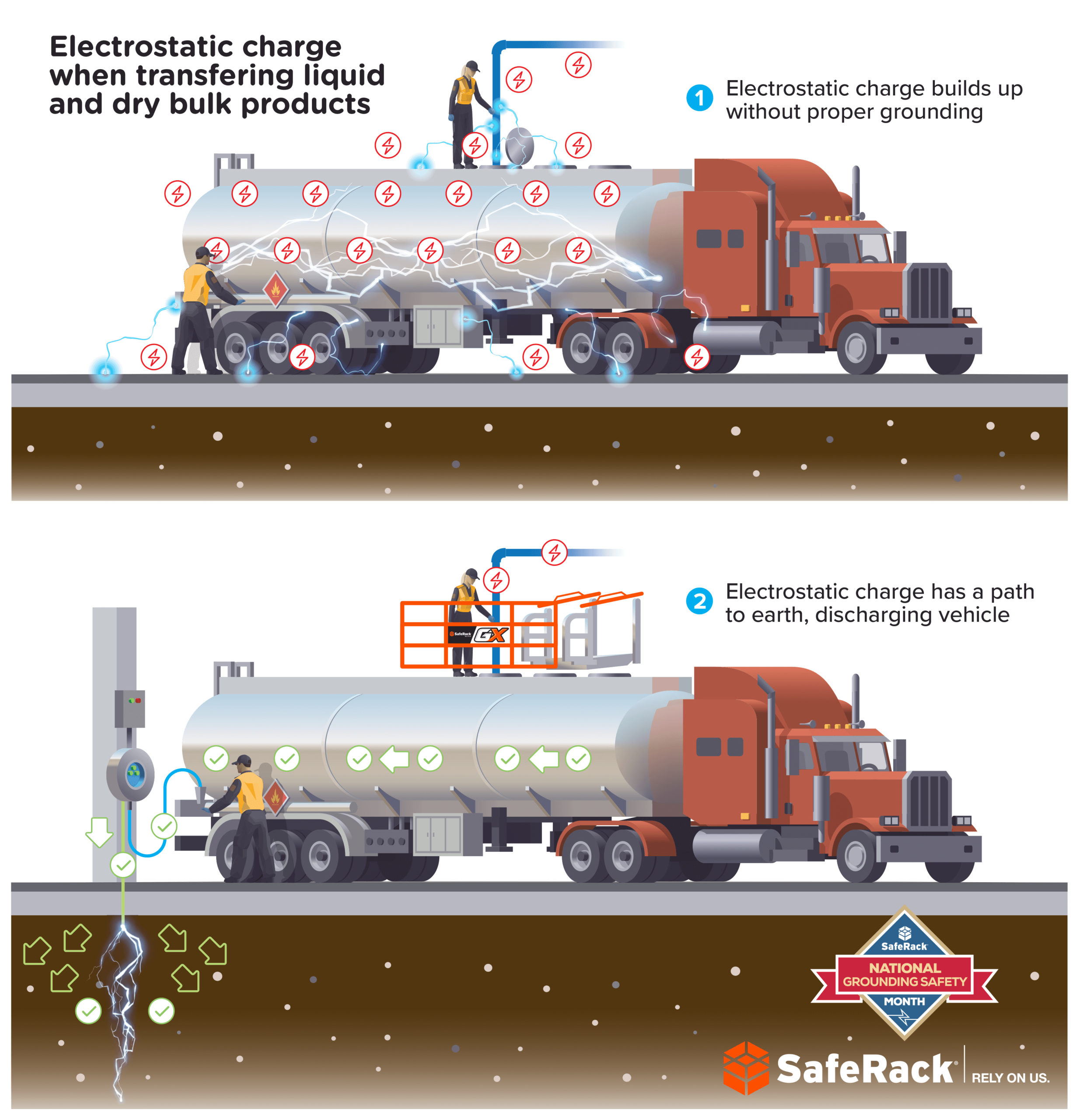

SafeRack & Newson Gale Host National Grounding Safety Month Promoting Static Electricity Awareness

ANDREWS, S.C.–(BUSINESS WIRE)–SafeRack, the global leader in industrial loading safety equipment has teamed up with Newson Gale, the leader in static control to designate August as Grounding Safety Month. When loading petrochemical or other combustible materials, static electricity safety and the importance of vehicle grounding cannot be overemphasized. Careful precautions must be taken to assess…

-

July is designated as Spill Prevention Month to promote awareness in industrial spill containment

Andrews, South Carolina, June 25, 2020 — SafeRack, the global leader in industrial loading safety equipment has teamed up with UltraTech International, the leading supplier of environmental compliance products to designate July as Spill Prevention Month. Experts from both companies conduct safety audits to help businesses create an action plan for avoiding spills and containing…

-

SixAxis Statement Regarding Hurricane Harvey

On behalf of the entire SixAxis family, our thoughts and prayers go out to all of those impacted by this devastating storm. We know for certain that many of our employees, dealers, and customers in the area have sustained significant damage and hardship as a result of this historical disaster. SixAxis is contributing $5,000 to…

-

New ways of thinking lead to opportunity and growth

By Andrel S. Langely SafeRack co-founders Fred Harmon and Rob Honeycutt stand in front of the global company’s 225,000-square-foot facility in Andrews, S.C. Not seeing any virtue in simply doing things the way they’ve always been done has led to grand things for SafeRack co-founders Rob Honeycutt and Fred Harmon. SafeRack started in 2003 when…

-

SafeRack LLC named supplier of choice for Holcim (US) and Lafarge North America Inc. plant and term

Holcim (US) and Lafarge North America Inc., US businesses of LafargeHolcim Ltd, One of the world’s leading suppliers of cement, aggregates, concrete and asphalt, have announced that they have selected SafeRack to be their exclusive provider of trailer loading gangways, platforms, and safety related loaded equipment for the entire US marketplace. Two months of joint…

-

A South Carolina Startup That Hacked The Industrial Process To Reach $100 Million In Revenue

As seen on Forbes.com By Christopher Steiner Rob Honeycutt’s success defies so many conventions within the entrepreneurial canon that it’s hard to pick which part of his tale merits telling first. As a salesman, he’s not supposed to be good with software. As somebody without a college degree, he’s not supposed to be able to, in a…