News

-

SafeRack Receives 2025 FMA Safety Award of Merit

SafeRack is proud to announce that we have once again received the 2025 Safety Award of Merit from the Fabricators and Manufacturers Association (FMA), marking another year of recognition for our dedication to workplace safety and operational excellence. Earning this award multiple years in a row highlights our team’s steadfast commitment to creating a safe…

-

ErectaStep Announces Strategic Leadership Promotions

ErectaStep Announces Strategic Leadership Promotions to Support Market Share Growth and Increased Product Demand Charleston, SC – June, 10, 2025 – ErectaStep, a leading innovator in modular metal stairs, work platforms, and safety access solutions for commercial and industrial markets, is proud to announce a series of executive promotions that reflect the company’s rapid market…

-

Jack Murphy Named President of SafeRack and ErectaStep

SafeRack and ErectaStep, industry leaders in industrial safety equipment and modular access solutions, are pleased to announce the promotion of Jack Murphy to President. In this expanded leadership role, Murphy will guide the strategic direction, operations, and continued growth of both brands, reinforcing their commitment to delivering innovative, American-made safety solutions to industries worldwide. Murphy…

-

ISO 14001 Audits with Zero Major Findings

Andrews & West Chester Locations Complete ISO 14001 Audits with Zero Major Findings

-

SafeRack 2025 Global Sales Summit

Celebrating Excellence in Safety and Service With the USS Yorktown as a backdrop in Mount Pleasant, South Carolina, SafeRack’s 2025 Global Sales Summit assembles our industry-leading sales team of RAMs (Regional Area Managers) to celebrate outstanding achievements. This event brings together key departments—including Marketing, Engineering, Vertical Market Specialists, Customer Service, Plant Operations, and our Executive…

-

A Heartfelt Christmas Message from SixAxis

At SixAxis, we understand dedication to doing the job right and the importance of safety above all else. This Christmas, we celebrate the hardworking individuals who give their all each day—not just for their teams at work, but for their loved ones waiting at home.

-

SixAxis Achieves ISO 14001:2105 Certification

We are proud to announce that our brands, SafeRack, Upside Innovations, and ErectaStep, have all achieved the ISO 14001:2015 certification for our environmental management system.

-

SafeRack Receives FMA Safety Award

SafeRack, LLC located in Andrews, South Carolina was recently chosen to receive a 2024 Safety Award of Merit from the Fabricators and Manufacturers Association (FMA). Open to all FMA company members, the FMA/CNA Annual Safety Awards recognize metal fabrication companies that adhere to excellence in safety. Sponsored by CNA, the endorsed business insurance carrier for…

-

SixAxis Welcomes Scott Harris as Chief Financial Officer

We are excited to announce the appointment of Scott Harris as the Chief Financial Officer of SixAxis. Scott, who initially joined us as Interim CFO, has quickly become an indispensable part of our team, contributing significantly to our strategy development and leading our budgeting process for the upcoming year.

-

SixAxis Welcomes Al Weggeman as Chief Executive Officer

SixAxis, LLC announced the appointment of Al Weggeman as Chief Executive Officer, following a thorough CEO search process.

-

Doug Odum Promoted to Chief Operating Officer at SixAxis

We are excited to announce Doug Odum’s promotion to Chief Operating Officer at SixAxis. This advancement is a testament to Doug’s remarkable journey with SixAxis, reflecting both the expansion of his role over the past year and his pivotal contributions to our company’s growth. In his new capacity, Doug will continue to spearhead the drive…

-

SafeRack Celebrates a Stellar 2023!

Mount Pleasant, SC – Amidst the backdrop of the USS Yorktown, SafeRack’s sales team recently celebrated a year marked by unwavering commitment to safety and customer excellence. This gathering in Mount Pleasant, South Carolina, celebrated achievements and reaffirmed our core mission: to provide safe access solutions and unparalleled service in the field by enhancing Collaboration and…

-

Boardroom Brilliance: A Unique Holiday Safety Vision

Our annual Christmas video is here! Crafted with love and a lot of laughs, it stars our team members’ adorable kids, embodying our simple yet profound belief: Safety is so fundamental that even a child understands it. This annual labor of love is our gift to you – our family, friends, customers, and partners.

-

Upside Expands With New Facility

Upside Innovations Expands with New Facility, Elevating Quality and Innovation SIXAXIS ANNOUNCES MAJOR EXPANSION WITH UPSIDE INNOVATIONS’ MOVE TO NEW, LARGER FACILITY CINCINNATI, OHIO NOVEMBER 28, 2023-–Upside Innovations, a leading provider of ADA & IBC-compliant access solutions and a SixAxis company, is excited to announce its upcoming move to a larger facility, a significant milestone…

-

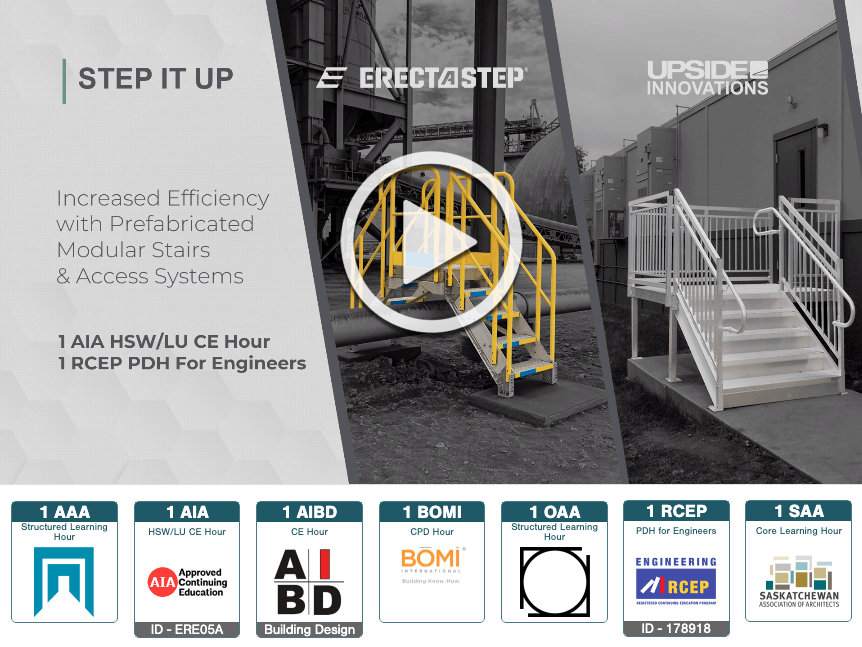

CE Course – Increased Efficiency with Prefabricated Modular Stairs, Access Systems, & Ramps

Earn CEU credits with our free one-hour online course that discusses prefabricated modular metal stairs, access platforms, and ramps. Participants will learn about the benefits and relevant codes from OSHA, IBC, and ADA regarding stairs, ladders, and handrails, but they will also learn how to specify modular stair components and configurations to facilitate code compliance…

-

Celebrating Record-Breaking Sales and Individual Performances

Beautiful downtown Charleston provided the historic backdrop for our International Sales Meeting this month. Individual performance milestones were celebrated as we marked yet another record-breaking year of sales for the SixAxis family of brands. Our continued focus on Commercial Excellence refers to our commitment to top-tier customer service, superior products, and a relentless pursuit of…

-

Safely Having a Wonderful Christmas Time

Enjoy our holiday sing-along. We promise it will make you smile.

-

Launch of Upside Innovations APEX and DOCK Step

SIXAXIS ANNOUNCES THE LAUNCH OF UPSIDE INNOVATIONS APEX AND DOCK STEP MODULAR ACCESS SYSTEMS CINCINNATI, OHIO OCTOBER 28, 2022 —Upside Innovations, a SixAxis company, has launched an innovative new modular access system. The APEX System is a modular, prefabricated line of ADA, IBC, and OSHA-compliant stairs, ramps, and canopies designed to improve safe access for businesses in a wide variety of industrial, commercial,…

-

SafeRack, a SixAxis Company Celebrates OSHA SHARP Designation

ANDREWS, SOUTH CAROLINA June 22, 2022 —Joining an elite group of businesses in the state of South Carolina, SafeRack, a SixAxis company and the global leader in industrial safety equipment and access systems, has been recognized as a model for safety and health excellence as determined by OSHA (Occupational Safety & Health Administration). The federal…

-

SafeRack Recieves ISO 9001:2015 Certificate

SafeRack Achieves ISO 9001:2015 Quality Management Certification of Registration ANDREWS, SOUTH CAROLINA August 30, 2022 —SafeRack, the global leader in industrial safety access, egress, and fall protection systems has been awarded the ISO 9001:2015 Certificate of Registration for Quality as determined by standards developed by the ISO (International Organization of Standardization). Awarded In May 2022,…

-

SafeRack Podcast – How to Prepare for a Successful Modular Stair & Ramp Installation

A podcast about truck spotting and why it’s important. In this episode of SafeRack Podcast, hosts Kenny Rogers and Ray Evans discuss the significance of proper truck spotting including topics such as loading arms and hoses, open and closed loading, ISOtainers, specialized safety cages, hatch access, as well as top and bottom unloading from truck…

-

SafeRack Podcast – Railcar BOLOs with Kenny and Ray

A podcast about truck spotting and why it’s important. In this episode of SafeRack Podcast, hosts Kenny Rogers and Ray Evans discuss the significance of proper truck spotting including topics such as loading arms and hoses, open and closed loading, ISOtainers, specialized safety cages, hatch access, as well as top and bottom unloading from truck…

-

SafeRack Podcast – Soft Tissue Injuries with Kenny and Ray

A podcast about truck spotting and why it’s important. In this episode of SafeRack Podcast, hosts Kenny Rogers and Ray Evans discuss the significance of proper truck spotting including topics such as loading arms and hoses, open and closed loading, ISOtainers, specialized safety cages, hatch access, as well as top and bottom unloading from truck…

-

SafeRack Podcast – Design-Build Services with Kenny and Ray

A podcast about truck spotting and why it’s important. In this episode of SafeRack Podcast, hosts Kenny Rogers and Ray Evans discuss the significance of proper truck spotting including topics such as loading arms and hoses, open and closed loading, ISOtainers, specialized safety cages, hatch access, as well as top and bottom unloading from truck…

-

SafeRack Podcast – Truck spotting with Kenny and Ray

A podcast about truck spotting and why it’s important. In this episode of SafeRack Podcast, hosts Kenny Rogers and Ray Evans discuss the significance of proper truck spotting including topics such as loading arms and hoses, open and closed loading, ISOtainers, specialized safety cages, hatch access, as well as top and bottom unloading from truck…

-

SafeRack secures patent for the innovation GX loading gangway.

SafeRack secures patent for the innovation GX loading gangway, the world’s most ergonomically advanced truck and railcar gangway. ANDREWS, SOUTH CAROLINA March 22, 2022 —SixAxis, the global leader in industrial bulk loading safety equipment, has secured a patent on the GX, the most ergonomically advanced and #1 selling gangway in North America. The original G4…

-

Lt. Governor Pamela Evette Visits SafeRack to Celebrate Women in Manufacturing

Lt. Gov. Pamela Evette, South Carolina’s first female Republican Lt. Governor visited SafeRack headquarters in Andrews, SC at an International Women’s Day event co-hosted by our parent company SixAxis and Women in Manufacturing (WiM), the only national and global trade association dedicated to supporting women working in the manufacturing industry. Lt. Governor Evette spoke about…

-

Banish unsafe stairs and equipment to the Land of Misfit Platforms and Steps.

Despite the craziness of the past year, we can be grateful that so many employers are improving their focus on workplace safety. In the spirit of the season, aspiring safety manager Herbie the Elf spreads the message of safety, making the world a safer place for everyone. Don’t let rickety, unsafe equipment ruin the Christmas…

-

Co-Founder & CEO of SixAxis Manufacturing to Step Down at the End of 2021, President Named Successor

Rob Honeycutt, Co-Founder & Chief Executive Officer, plans to step down from his current role as CEO at the end of 2021. The Board of Directors has appointed Jeff Reichert to succeed Honeycutt as Chief Executive Officer on January 1, 2022.

-

SafeRack Receives Safety Award of Merit from FMA

SAFERACK RECEIVES SAFETY AWARD OF MERIT FROM FABRICATORS & MANUFACTURERS ASSOCIATION Andrews, SC., August 9, 2021 – Download Press Release SafeRack was recently chosen to receive a 2021 Safety Award of Merit from the Fabricators & Manufacturers Association, International (FMA). Open to all FMA company members, the FMA/CNA Annual Safety Awards recognize metal fabrication companies…