Tracy Mikulec

-

Co-Founder & CEO of SixAxis Manufacturing to Step Down at the End of 2021, President Named Successor

Rob Honeycutt, Co-Founder & Chief Executive Officer, plans to step down from his current role as CEO at the end of 2021. The Board of Directors has appointed Jeff Reichert to succeed Honeycutt as Chief Executive Officer on January 1, 2022.

-

SafeRack Receives Safety Award of Merit from FMA

SAFERACK RECEIVES SAFETY AWARD OF MERIT FROM FABRICATORS & MANUFACTURERS ASSOCIATION Andrews, SC., August 9, 2021 – Download Press Release SafeRack was recently chosen to receive a 2021 Safety Award of Merit from the Fabricators & Manufacturers Association, International (FMA). Open to all FMA company members, the FMA/CNA Annual Safety Awards recognize metal fabrication companies…

-

Press Release – Upside Innovations Acquisition Expands Product Range

Falfurrias Capital Partners’ SixAxis manufacturing to expand safety and access product solutions with the acquisition of Upside Innovations Deal combines complementary firms in modular, mass-customized manufacturing of ramps, stairs, platforms and handrails CHARLOTTE, NORTH CAROLINA (June 2, 2021) – Charlotte-based private equity firm Falfurrias Capital Partners today announced it has facilitated the add-on acquisition…

-

Press Release – SixAxis launches Liquid Transfer Group

SixAxis launches Liquid Transfer Group, welcoming Joe Natale as Senior Business Development & Operations Specialist Andrews, South Carolina— March 31, 2021 SixAxis announced the launch of Liquid Transfer Group, a consulting group that specializes in terminal loading projects. The appointment of Joe Natale as Senior Business Development and Operations specialist helped kick off the new…

-

The turkeys are smoked!

In 2020 we felt it would be appropriate to take a different approach to our annual Christmas video and decided to make a difference.

-

SafeRack’s GX Awarded Fall Protection/Prevention Product of the Year

GX Awarded 2020 Fall Protection/Prevention New Product of the Year by Occupational Health & Safety Andrews, South Carolina, October 5, 2020 — The Occupational and Health Safety New Product of the Year Awards were announced last month and SafeRack’s new GX Gangway claimed top prize in the Fall Protection/Prevention category. Now in their 11th year,…

-

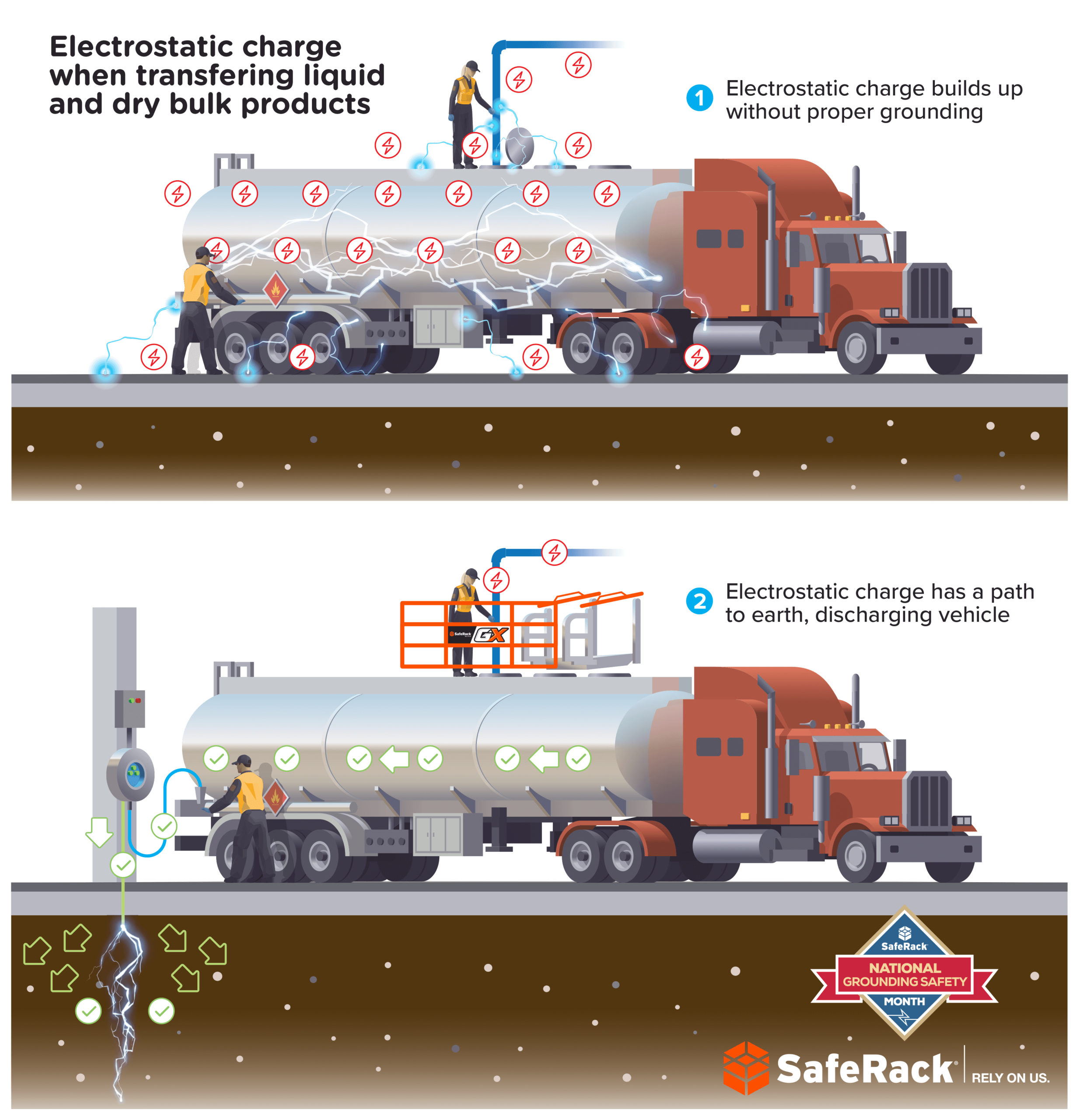

SafeRack & Newson Gale Host National Grounding Safety Month Promoting Static Electricity Awareness

ANDREWS, S.C.–(BUSINESS WIRE)–SafeRack, the global leader in industrial loading safety equipment has teamed up with Newson Gale, the leader in static control to designate August as Grounding Safety Month. When loading petrochemical or other combustible materials, static electricity safety and the importance of vehicle grounding cannot be overemphasized. Careful precautions must be taken to assess…

-

July is designated as Spill Prevention Month to promote awareness in industrial spill containment

Andrews, South Carolina, June 25, 2020 — SafeRack, the global leader in industrial loading safety equipment has teamed up with UltraTech International, the leading supplier of environmental compliance products to designate July as Spill Prevention Month. Experts from both companies conduct safety audits to help businesses create an action plan for avoiding spills and containing…

-

Press Release – GX Loading Gangway

SafeRack introduces the GX loading gangway, the world’s most ergonomically advanced loading gangway for truck and railcar. Andrews, South Carolina, March 10, 2020 — SafeRack, the global leader in industrial bulk loading safety equipment just announced the production of their most ergonomically advanced gangway. The new GX Gangway is the next generation of North America’s…

-

COVID-19 Update from SafeRack

Our hearts go out to all individuals impacted by the COVID-19 pandemic. We sincerely hope the actions being taken across our country will stop the spread of the virus and help protect everyone affected directly by infection or indirectly by its impact on jobs, schooling, or safety. We are open for business and our intent…

-

Have you lost the true meaning of Christmas?

The new Christmas video is live. It’s our 10th year doing these, and we think it turned out great.

-

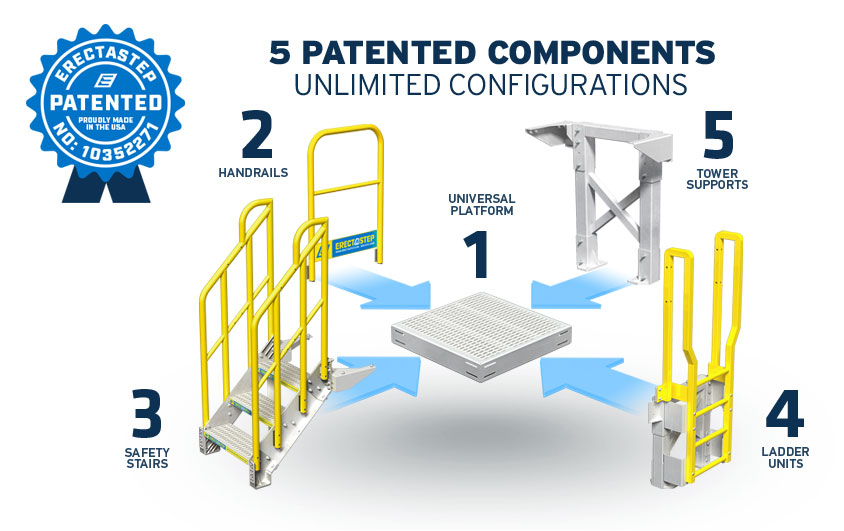

SixAxis Secures Utility & Design Patents on Ingenious ErectaStep Products

Andrews, South Carolina – October 29, 2019 — Adding to a growing list of over 24 innovative proprietary industrial designs, SixAxis, LLC secured U.S. patent 10,358,871 in July of this year on behalf of its ErectaStep brand. The product line is ingeniously simple, composed of 5 OSHA compliant modular components designed with an infinite number…

-

ErectaStep’s “The 8th Wonder of the World” saga continues

“The 8th Wonder of the World” saga continues as ancient Egyptian Pharaoh Khufu chooses SixAxis’ ErectaStep to keep pyramid builders safe in an ingenious media campaign entitled, “The Mummy Returns.” Andrews, South Carolina – October 22, 2019 — Manufactured with the strict brand ethos that fall-prevention and safety products can be innovative, fast to ship,…

-

A Major Safety Milestone Reached for SafeRack: 500 Days Injury Free

On Tuesday, April 30th SafeRack celebrated 500 days without any injuries in their manufacturing plant. SafeRack, the leading industrial manufacturer of safety access equipment and an OSHA and IBC compliant company is setting the trend of putting safety first for employees and companies locally and across America. As SafeRack’s influence grows across a number of…

-

SixAxis Welcomes Jack Murphy as VP of Sales

SixAxis announced the appointment of Jack Murphy to the executive leadership team on January 7th, 2019. Murphy stepped into his role as Vice President of Sales on January 21st, 2019. SixAxis’ innovative products have been giving businesses in all sectors the competitive edge globally since 2003. Their award-winning products and patents are created under brands…

-

SixAxis’ ErectaStep touted as the “8th Wonder of the World” in an unprecedented national media campaign

Andrews, South Carolina—Already recognized as the world leader in manufacturing loading platforms and fall-protection products, SixAxis launched a clever and comedic national media campaign through their in-house creative marketing agency red7 last week promoting ErectaStep, their line of industrial modular stairs, catwalks, and handrails designed to increase safety and efficiency for some of the world’s…

-

SafeRack Welcomes Jason Merschat as VP of Operations

SafeRack, the world’s largest manufacturer of truck and railcar loading platforms and safety equipment, is proud to announce and welcome Jason Merschat as VP of Operations. Mr. Merschat will be responsible for expanding the growth rate while meeting and exceeding the needs of customers in terms of delivery and quality. SafeRack has experienced an increase…

-

SafeRack Welcomes Eric Grothaus as Director of Human Resources

SafeRack, the world’s largest manufacturer of truck and railcar loading platforms and safety equipment, welcomed Eric Grothaus as Director of Human Resources in July. Grothaus will be responsible for attracting and retaining the very best candidates for the company. Grothaus joins the SafeRack team after a lengthy career in Human resources working for Cincinnati…

-

Announcing MarinaStep, an innovative line of ship and marine gangways

FOR IMMEDIATE RELEASE: August 7, 2018 CONTACT INFORMATION: Brian Dieffenderfer – Director, Business Development – MarinaStep 843-359-5679 / bdieffenderfer@marinastep.com 866-761-7225 SAFERACK PROUDLY INTRODUCES MARINASTEP, SAFE ACCESS RAMPS AND GANGWAYS FOR SHIP AND BARGE ACCESS. Andrews, South Carolina – SafeRack, the world’s largest manufacturer of truck and railcar loading platforms and safety equipment, is excited…

-

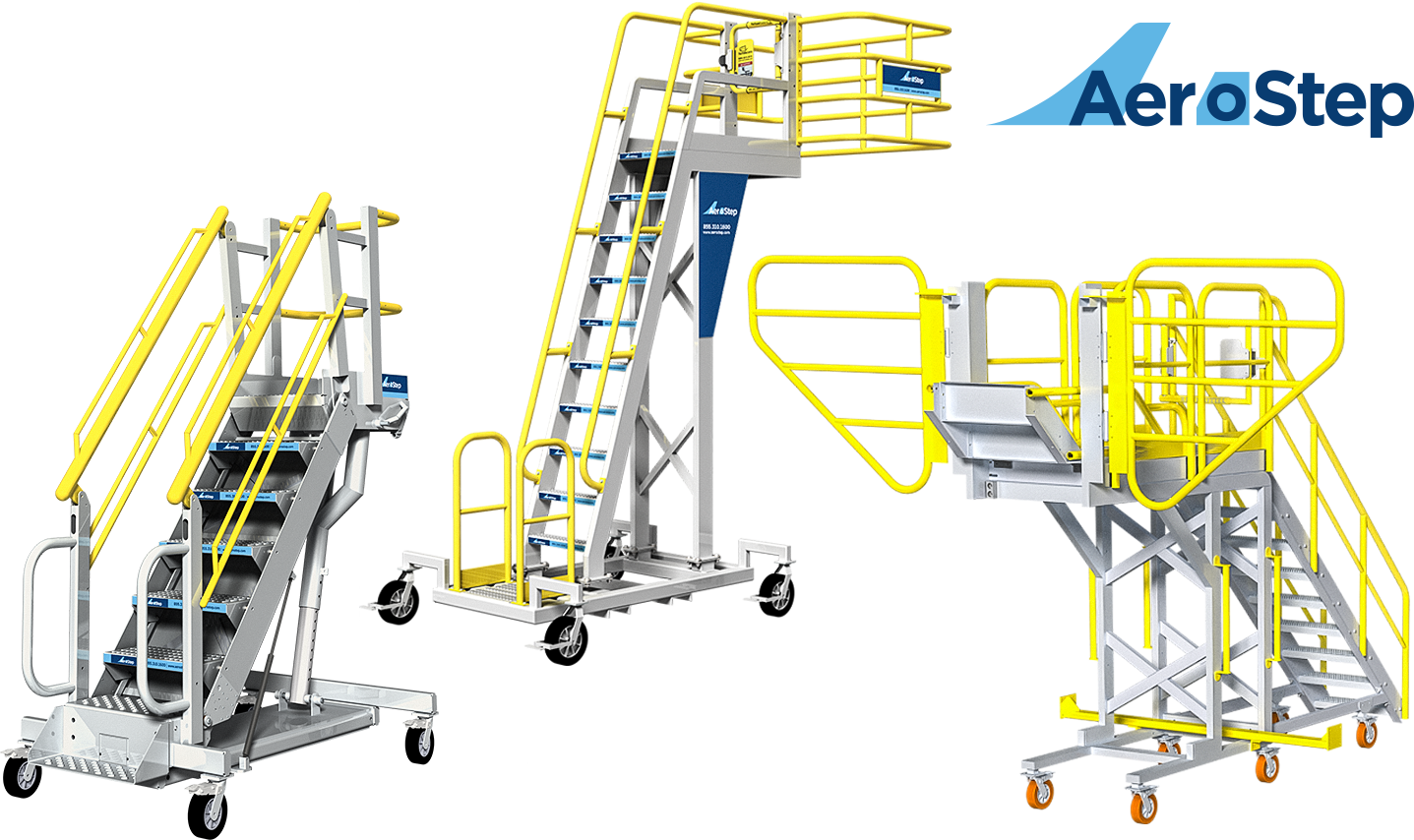

SafeRack Introduces AeroStep, Mobile Stair Units for Aviation and Aerospace

SafeRack, the leading manufacturer of truck and railcar loading platforms and safety equipment, is excited to announce AeroStep, a specialized line of rolling stairs and access platforms for aerospace and aviation industries. AeroStep’s mobile stairs have the stability of a fixed platform, but are highly mobile and can be precisely positioned against even the most…

-

Falfurrias Capital Announces Strategic Investment in SixAxis

Falfurrias Capital Announces Strategic Investment in SixAxis SixAxis is a leading manufacturer of safety equipment, including SafeRack, ErectaStep brands CHARLOTTE, N.C. (Sept. 21, 2017) – Falfurrias Capital Partners (“FCP”), a Charlotte-based private equity firm focused on investing in growth-oriented, middle-market businesses, and SixAxis LLC (“SixAxis”), the leading manufacturer of advanced products that increase worker…

-

SixAxis Statement Regarding Hurricane Harvey

On behalf of the entire SixAxis family, our thoughts and prayers go out to all of those impacted by this devastating storm. We know for certain that many of our employees, dealers, and customers in the area have sustained significant damage and hardship as a result of this historical disaster. SixAxis is contributing $5,000 to…

-

ErectaStep Expands Facility and Product Line

ANDREWS, SOUTH CAROLINA — (August, 16, 2017) – Continuing with their commitment to providing world class stairs and access platforms, today, ErectaStep announces the introduction of three new products designed to fill the demand for higher quality metal stair kit solutions to serve the commercial and architectural marketplaces. ErectaStep is to begin production of four…

-

New ways of thinking lead to opportunity and growth

By Andrel S. Langely SafeRack co-founders Fred Harmon and Rob Honeycutt stand in front of the global company’s 225,000-square-foot facility in Andrews, S.C. Not seeing any virtue in simply doing things the way they’ve always been done has led to grand things for SafeRack co-founders Rob Honeycutt and Fred Harmon. SafeRack started in 2003 when…

-

PerfectaStep and RollaStep partner w/ NASA

Boeing’s CST-100 Starliner Makes Major Move for U.S. Return to Human Space Flight In an operation at Kennedy Space Center involving minute movements and precise placement, the pieces of the first CST-100 Starliner test article became a capsule. The test article will help verify the manufacturing method, the materials, and the parts being created by…

-

SafeRack LLC named supplier of choice for Holcim (US) and Lafarge North America Inc. plant and term

Holcim (US) and Lafarge North America Inc., US businesses of LafargeHolcim Ltd, One of the world’s leading suppliers of cement, aggregates, concrete and asphalt, have announced that they have selected SafeRack to be their exclusive provider of trailer loading gangways, platforms, and safety related loaded equipment for the entire US marketplace. Two months of joint…

-

About the buying experience

How one manufacturer streamlined quoting and grew 500 percent in six years. Metal fabricators have a history of growing through word-of-mouth. Many companies go for years, sometimes generations, without hiring a single salesperson. It’s just the nature of this manufacturing sector dominated by small, multigenerational family shops. Few say their company is “sales-driven.”

-

Georgetown County Chamber of Commerce announces annual award winners

Georgetown County Chamber of Commerce names SafeRack as “Business of the Year”

-

A South Carolina Startup That Hacked The Industrial Process To Reach $100 Million In Revenue

As seen on Forbes.com By Christopher Steiner Rob Honeycutt’s success defies so many conventions within the entrepreneurial canon that it’s hard to pick which part of his tale merits telling first. As a salesman, he’s not supposed to be good with software. As somebody without a college degree, he’s not supposed to be able to, in a…

-

Tech Trends for 2016

As seen on IndustryWeek.com By Matt Lawell Drones, virtual reality, augmented reality and the Internet of Things (Industrial and otherwise) will top all sorts of buzzword lists this year. But what about the new manufacturing tech that has been glossed over a little? Here are some of the developments that could help you transform for…